GC-100DW

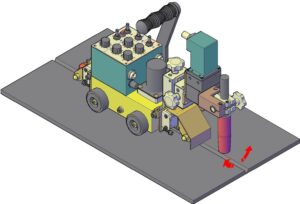

Second-Pass Weaving welding carriage (improved curved plate Butt joint)

This is a dedicated weaving carriage for welding the butt joint of the curved plate.

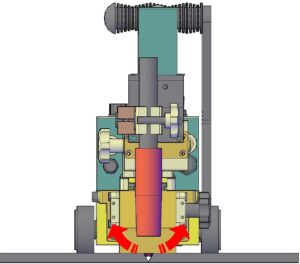

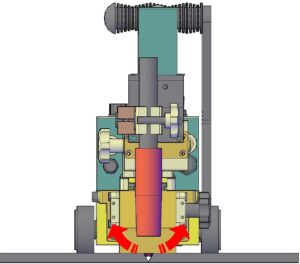

Guide rollers track along the straight and curved plate improvement sections, supporting stable weaving welding.

Precise weaving control: Weaving width, left/right pause time, center movement, etc. can be precisely set digitally to achieve the desired welding angle in a single pass.

Additionally, the torch has a central position when weaving stops, making the next operation convenient.Stable Constant Speed Driving: The control controller, developed after extensive research, adopts a microcomputer control method that effectively blocks high frequencies and various noises.

This enables stable, constant driving in any working environment.Excellent durability: Minimizes gear backlash for precise operation, maximizing weld quality and extending equipment life.

Easy to attach and detach: Attach or detach your equipment quickly and easily.

특허 제 : 10-0995460 호

| Specification | GC-100DW | |||||||||

| Driving Part | Dimensions | L161 * W486 * H272 | ||||||||

| Weight | 8.9kg | |||||||||

| Input power | AC 85V~260VA 60Hz /50Hz | |||||||||

| Driving Method | 4 WHEELS DRIVE | |||||||||

| Traveling Speed | 0~ 1000 mm/min | |||||||||

| Torch adjustment | Right / Left : 32 mm Up / Down : 32mm | |||||||||

| driving motor | DC 24VA / 3000 rpm 250 : 1 | |||||||||

| Weaving Part | Weaving motor | SERVO MOTOR | ||||||||

| Weaving width | Max. 25mm | |||||||||

| Weaving speed | 60 cycles/min (Maximum weaving width: 25mm) | |||||||||

| Weaving stop | Left 0 ~ 2 sec, Right 0 ~ 2 sec | |||||||||

| Weaving Control | Weaving, ON, OFF, weaving speed, left weaving width, right weaving width, weaving left and right pause time | |||||||||

| Power lamp, Start, Stop, Speed, Forward/Backward, Welding, Non-Welding | ||||||||||

Weaving mode

Welding Position